About PTC Heaters

Innovative, flexible, printed heating elements composed of PTC materials heat evenly across their entire surface. They self-regulate to a specified temperature without the need for external diagnostics or controls.

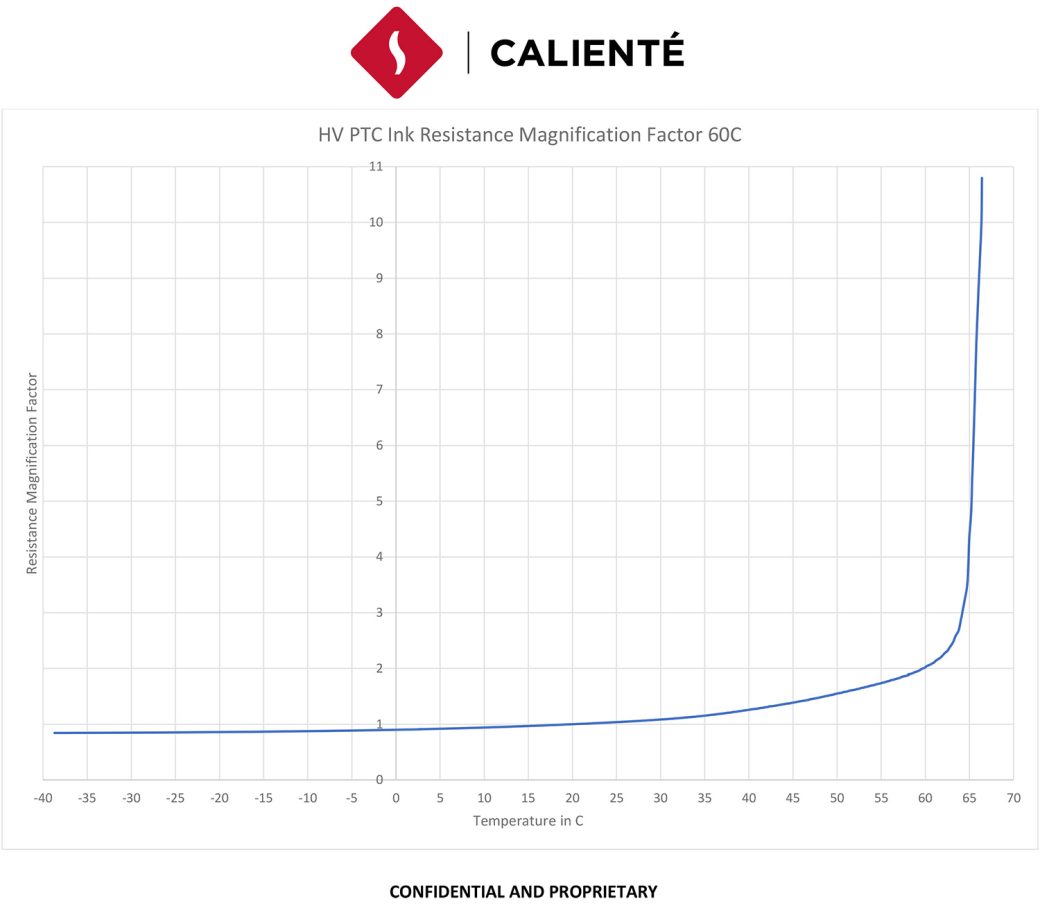

What is “PTC”?

PTC stands for Positive Temperature Coefficient. These are materials that exhibit a positive resistance change with an increase in temperature. When voltage is applied, the resistance increases and limits the electrical current to the heater, along with outputted wattage.

SAFE & DURABLE

The primary appeal of Caliente Termico’s PTC heaters is that they are self-regulating, providing a built-in safety factor to their design. The self-regulating nature reduces the need for additional fuses, controller units, etc. All this results in fewer field problems, greater safety, and lower power requirements. In addition, they can be built with UL Component Recognition governing long-term electrical safety.

UNIFORM PERFORMANCE

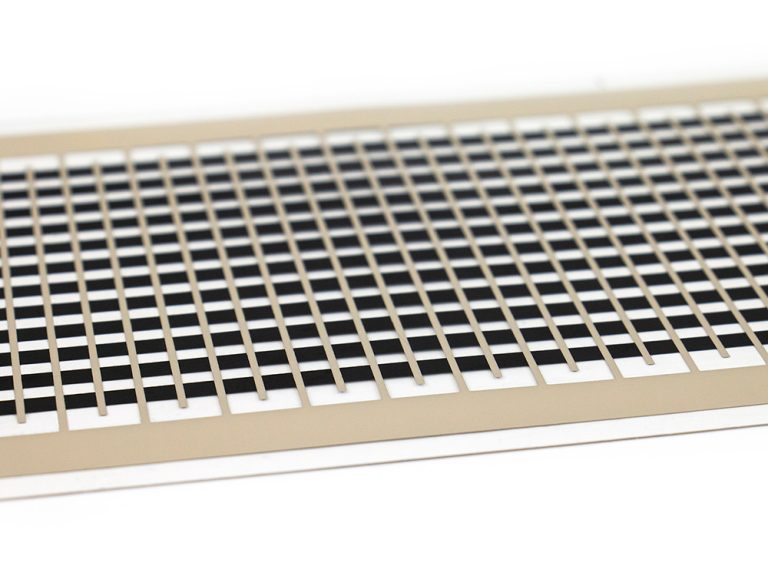

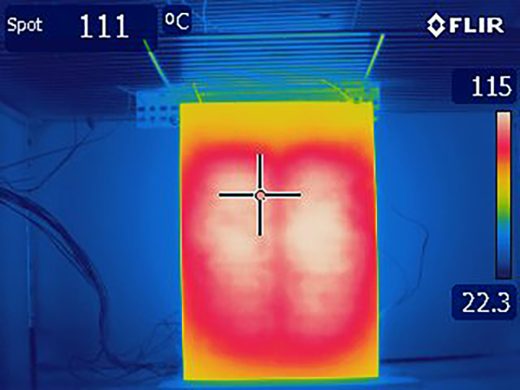

PTC heaters provide even, uniform heating without the hot spots associated with traditional technologies like heater wire. PTC heaters achieve precise temperatures quickly, with uniform temperature distribution and superior heat transfer. Heaters can also be designed with multiple temperature zones.

Caliente Termico utilizes high-resolution thermal imaging equipment to monitor the quality of the temperature and uniformity of the heat output generated.

INCREDIBLY VERSATILE

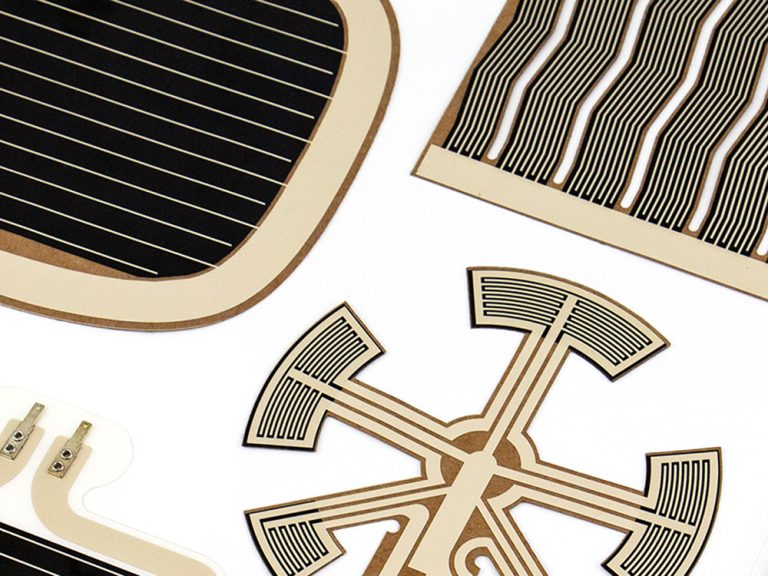

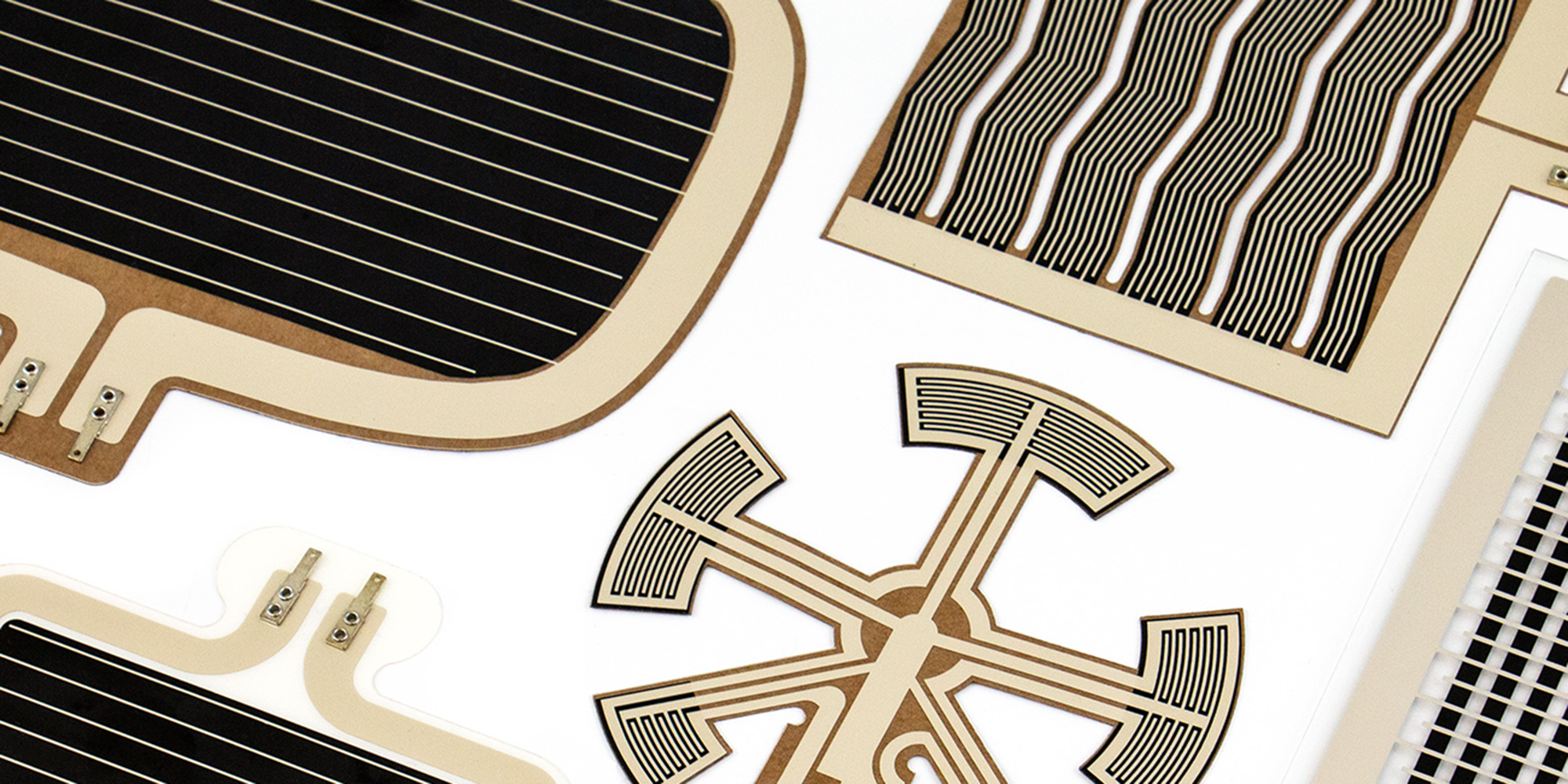

Thin, flexible, and available in nearly any shape, PTC heaters are suitable for many applications and can run on DC or AC power, from 5 volts to 800 volts. Caliente Termico’s unique PTC heaters are manufactured to our customer’s specific requirements using unlimited sizes, shapes, and heat configurations.

Our specialized 4-post screen printing equipment is capable of printing the required conductive and PTC inks to extremely precise tolerances. Plus, they are thinner and more flexible than forced air and silicone heaters, and more robust than graphite heaters.

Learn more about the variety of markets & applications for PTC heaters

ENERGY EFFICIENT

PTC heaters require less energy and operate at lower temps than traditional technologies which saves on battery life. Caliente Termico’s PTC heaters utilize additive conductive circuitry, which is more environmentally friendly than the subtractive chemical etching process used in copper foil heaters used for silicone heaters.

Due to the energy savings from using less power, combined with the elimination of components and controls, PTC heaters typically result in a lower total installed cost vs. most of the common heater constructions available today (copper etched foil, silicone rubber, forced air and graphite heaters).

Materials used to create our PTC heaters are corrosion resistant and stand up to physical damage such as cuts, piercing, and folds without producing unsafe temperature spikes. They can operate in the temperature extremes of outdoor environments.